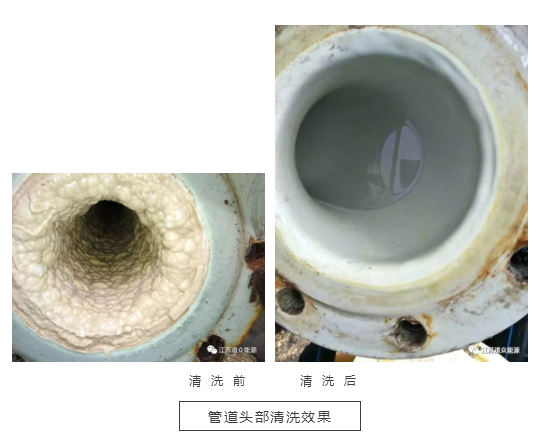

Ca, Mg and Na salt deposited on the surface of the seawater intake pipeline of nuclear power plant unit during long-term use can reduce the cross-section area of the pipeline and affect the normal use of the pipeline. Chemical cleaning is needed to remove dirt and restore the pipeline to be smooth.

After on-the-spot investigation and the introduction and guidance of the professional engineer of the power plant, our company adopts the short-tube test and analysis mechanism; partial implementation is easy and difficult; optimization scheme and step-by-step implementation scheme of pipe cleaning to ensure the effectiveness and reliability of the project implementation process, while meeting the owner's time limit requirements.

After the cleaning stage, open the flange at the entrance, and check the clearance rate in the pipeline up to 99%. The flow rate at the outlet of the charging pump has increased significantly, and the flow rate test is about 92.4 m/h. The corresponding value of the electromagnetic flow converter is more than 75%. The anti-corrosion coating has no obvious scratch, which fully meets the relevant requirements of the nuclear power plant.